Why You Need A Plastic Coated Wire

페이지 정보

본문

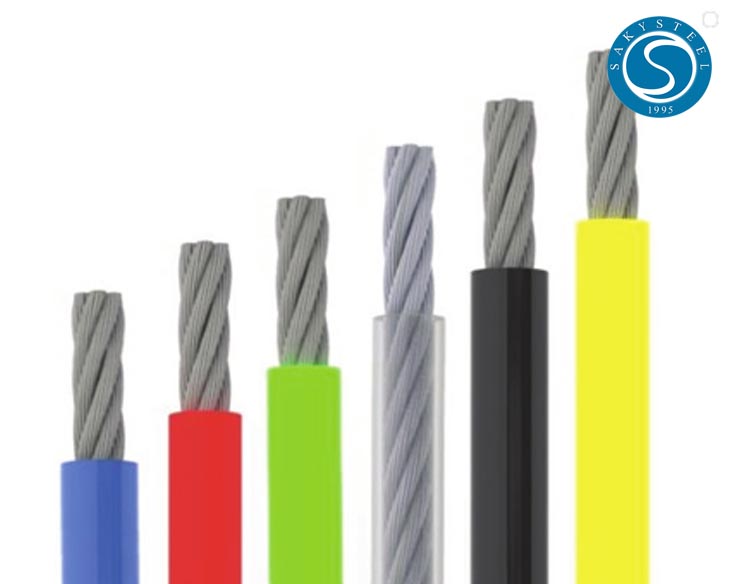

Compared to wireless transmission twisted pair and coaxial cables are much less delicate to electromagnetic interference. Installation of the twisted pair cable is simple, and it is a lightweight cable. For indoor purposes, the jacketed fiber is mostly enclosed, along with a bundle of versatile fibrous polymer energy members like aramid (e.g. Twaron or Kevlar), in a lightweight plastic cover to kind a easy cable. 7 strands composed of 19 filler wires present this cable with strength and flexibility. SINTERBERG®, registered mark in 1997, is the results of probably the most superior strategies in plastic-coating wires. Our premium heavy duty plastic coated wire mesh brings together form and function perfectly whether or not you are looking to enclose a flower bed, mark out a vegetable patch or create a safe space for your pets. Cable ties are typically designed as single-use gadgets, nevertheless they are often reopened with little or no damage by inserting a small flat object between the ratchet and the pawl, and pulling the pawl out. With custom extruded plastic coating, you can find the suitable jacketing solution in your metallic wiring, bars, and tubing wants. Metal bars provide energy and reliability to a construction or piece of machinery, whereas plastic coating helps stop accidents and makes the product more visually appealing to shoppers.

Plastic coating provides chemical resistance that extends the life of scientific instruments. It also adds a layer of safety in functions the place electricity is carried out. Plastic coating also provides safety from the elements, which is particularly useful in municipal initiatives, where price and longevity are key issues. Plastic coating can enhance using virtually any steel, including steel, aluminum, copper, bronze, brass, nickel, and alloys. Materials that conduct electricity and heat might be made safer and simpler, with out compromising quality. PVC coated wire is materials with a further layer of polyvinyl chloride or polyethylene on the floor of the annealed wire, galvanized wire and other materials. Its clean surface allows for straightforward bending, shaping, and cutting, making it a versatile alternative for a wide range of purposes. Plastic-coated instruments will be way more thoroughly cleaned and sterilized, making it a great solution for industrial functions. The detailed price depends on the quantity you want as nicely as the coating, wire gauge, and many others. However, you don’t have to worry a lot about the value, we will offer reductions for patrons who buy in massive portions.

Plastic coating provides chemical resistance that extends the life of scientific instruments. It also adds a layer of safety in functions the place electricity is carried out. Plastic coating also provides safety from the elements, which is particularly useful in municipal initiatives, where price and longevity are key issues. Plastic coating can enhance using virtually any steel, including steel, aluminum, copper, bronze, brass, nickel, and alloys. Materials that conduct electricity and heat might be made safer and simpler, with out compromising quality. PVC coated wire is materials with a further layer of polyvinyl chloride or polyethylene on the floor of the annealed wire, galvanized wire and other materials. Its clean surface allows for straightforward bending, shaping, and cutting, making it a versatile alternative for a wide range of purposes. Plastic-coated instruments will be way more thoroughly cleaned and sterilized, making it a great solution for industrial functions. The detailed price depends on the quantity you want as nicely as the coating, wire gauge, and many others. However, you don’t have to worry a lot about the value, we will offer reductions for patrons who buy in massive portions.

The need for a particular characteristic or combination of traits, resembling pulling energy, flexibility, or the lowest coefficient of friction, dictates the type of innerduct required. The pressure relief "boot" that protects the fiber from bending at a connector is coloration-coded to indicate the type of connection. Connectors with a plastic shell (resembling SC connectors) usually use a coloration-coded shell. This supplies added worth for the community and responsible use of tax dollars. The relatively simple strategy of plastic jacketing can lead to important lengthy-time period financial savings for your online business or group. Plastic coated metals final longer and can withstand harsh situations which are simpler for workers and shoppers to handle. The external PVC coating is firmly glued to the metallic wire with high resistance resins which forestall any flaws or detachment of the coating even beneath the heaviest working conditions. SINTERBERG® wire is the best solution to all industrial requirement for making plasticated wire merchandise thanks to its malleability and resistance. Because of the sintering process a perfect adhesion of the plastic with the wire is guaranteed. The metallic core is formed by a hot-galvanized mild steel wire with adherent and uniform coating which ensures excellent adhesion of the plastic and absolute protection.

The coating adheres firmly and evenly to the wire, providing good safety for the wire. The coating is firmly and evenly hooked up to the wire, which has the traits of anti-corrosion and anti-rust, thus making the wire protected. Coated wire has all the identical advantages as customary, high-high quality wire, with the added bonuses of security and ease of use. These coatings offer a quantity of advantages within both industrial and commercial contexts and can be custom-made for any steel wires, bars, or tubing. Industrial and industrial purposes for steel tubing and bars often require metal parts to maintain stable temperatures. The primary perform of plastic-coated metal tubing is to conduct liquids and gases in industrial or business contexts. Plastic coated steel bars are a perfect solution for each industrial machinery and public-facing shopper merchandise. In case you are on the lookout for a wire with longer life, then it's your greatest selection. How to prevent PVC Coated Wire from Rusting? PVC Coated Wire Application: The most well-liked use for PVC coated wire is in the construction of chain link fences for industrial security fences, freeways and tennis courts. If you buy a product or register for an account by means of a link on our site, we could obtain compensation.

The coating adheres firmly and evenly to the wire, providing good safety for the wire. The coating is firmly and evenly hooked up to the wire, which has the traits of anti-corrosion and anti-rust, thus making the wire protected. Coated wire has all the identical advantages as customary, high-high quality wire, with the added bonuses of security and ease of use. These coatings offer a quantity of advantages within both industrial and commercial contexts and can be custom-made for any steel wires, bars, or tubing. Industrial and industrial purposes for steel tubing and bars often require metal parts to maintain stable temperatures. The primary perform of plastic-coated metal tubing is to conduct liquids and gases in industrial or business contexts. Plastic coated steel bars are a perfect solution for each industrial machinery and public-facing shopper merchandise. In case you are on the lookout for a wire with longer life, then it's your greatest selection. How to prevent PVC Coated Wire from Rusting? PVC Coated Wire Application: The most well-liked use for PVC coated wire is in the construction of chain link fences for industrial security fences, freeways and tennis courts. If you buy a product or register for an account by means of a link on our site, we could obtain compensation.

- 이전글Ten New Age Methods To Find Top-rated Certified Daycares In Your Area 25.03.18

- 다음글Hyundai Elantra GT 2013 à jeter : Trouvez Votre Compacte Idéale 25.03.18

댓글목록

등록된 댓글이 없습니다.