Membrane Filter Press

페이지 정보

본문

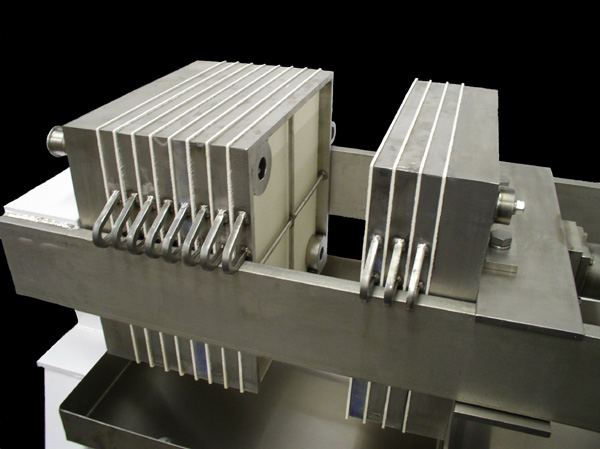

This design can pass clear water via the washing port of the filter plate to clean the filter cake to make sure the elimination of any remaining impurities. Compressed air can be handed by means of the washing port to dry the filter cake. This is particularly advantageous in applications the place filter cake purity is important, comparable to in the pharmaceutical and food industries. When the plates come collectively the 2 recessed plates type the chamber where the filter cake is formed. As soon as the cake is formed contained in the chamber the plates are pulled apart and the cake is able to discharge freely as it is no longer trapped contained in the frame, as it was within the older ? The important thing distinction being that a flexible membrane can also be added between the online of the plate and where the filter cake is formed. The membrane plate and frame filter press manufacturers can then be positioned next to a recessed plate in what is called a ?

5. Sludge discharge: Once the filtration course of is full, the filter cake is removed from the press. The filter cake is discharged by opening the press, and might be collected in a container or conveyed to a further processing step. 6. Hydraulic system: The filter plates are linked to a hydraulic cylinder that's used to apply strain to the filter cake during the filtration process. As sludge is introduced on the belts, water is squeezed out through the fabric by rollers. The belts’ movement via the press permits for optimal elimination of water, abandoning a drier cake. Drive mechanisms allow the movement of the filter belts. This usually involves motors and gearboxes that provide the required torque for belt development.

Distributor & engineer of process systems including turnkey techniques or troubleshooting existing techniques & components. Make the most of a large number of pneumatic, electrical, & mechanical control products for for handbook, computerized & robotic operation. Producer of commonplace and customized chemical process equipment together with catalyst chemical techniques. In a position to ship as much as sixteen chemicals. Also, filter cake launch is usually simpler with a recessed plate. When the press is opened, and the plates are shifted, the cake either falls out or is shortly scraped off the cloths using a spatula. Cake release is probably not as quick with a plate and body press, because the filter cake is held by a non-tapered frame and may require extra manipulation for elimination. Q How much does Chemical Process Equipment price? The price of a Chemical Process Equipment can range broadly depending on its measurement, capabilities, and complexity. 5000000 per Piece. It is important to analysis and evaluate completely different fashions and options to seek out the perfect Chemical Process Equipment to your wants and funds. Q What factory makes Chemical Process Equipment?

During the filtration process, the suspension to be filtered (feed) is introduced to the filter press. Strain is then utilized, forcing the liquid (filtrate) to pass via the filter media while retaining the stable particles (filter cake) on the surface of the media. Because the filtration progresses, the filter cake thickness increases, resulting in an increase in stress resistance. Membrane filter plates similar to built-in rubber-membrane filter plates and polypropylene-membrane filter plates. Distributor of new and used filter press plates. Numerous types embody ductile iron, forged iron, stainless steel, polypropylene and membrane. Upkeep and press companies are additionally obtainable. Manufacturer of commonplace & custom filter components & parts together with filter press plates. Other filter components & components akin to filter elements, filter luggage, filter screens, filter leaves, filter plates, filter cloth, O-rings, gaskets, hydraulic cylinders, valves & controls are also obtainable. Capabilities embrace CAD/CAM designing, engineering, prototyping, CNC machining, turnkey manufacturing, welding, tooling, ending, assembling & testing. Repairing, preventive upkeep, upgrading & refurbishing services can be found for filtration gear & elements. Manufacturers rep. of filter press aftermarket accessories including plates. Customized boiler & filter press plates. Custom metallic fabrications, architectural designs, custom perforated & louvered grilles, railings, enclosures, panels, frames, registers, louvers, cladding, canopies, marquis & roofing merchandise.

- 이전글What's The Job Market For Buy C1 E License Online Professionals? 25.03.07

- 다음글The Best Order A2 Driver's License Online Gurus Are Doing Three Things 25.03.07

댓글목록

등록된 댓글이 없습니다.